Submit a Request and Get a Free Consultation

Submit a request, and we will contact you to provide consultation on any questions

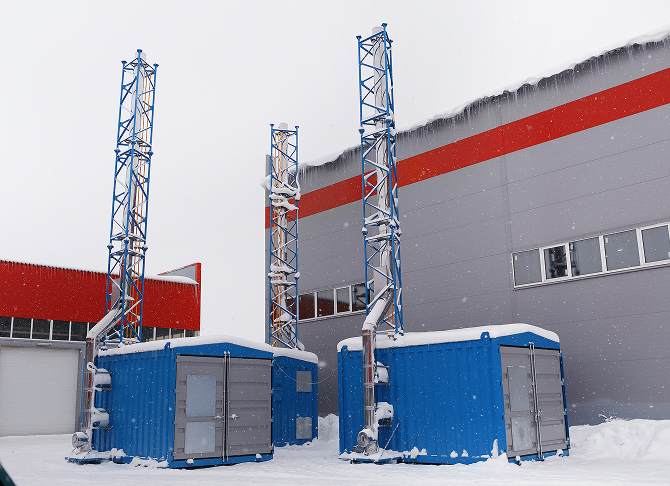

Gas-Fueled Air Heating Modular Units

Gas-Fueled Air Heating Modular Units

The LS series gas modular air heating units are designed for indirect heating of supply air in ventilation systems of lightweight individual enclosures for gas pumping units, as well as other premises to ensure sanitary and hygienic working conditions for maintenance personnel during scheduled maintenance. The installation is a fully factory-assembled equipment complex, including all necessary units, devices, machines, control and monitoring instruments, mounted in a block-container.

- Таблица 1

Indicator Name Specifications Rated Heat Output, kW 40-10000 Rated Thermal Power, kW 40-10000 Minimum Heat Output, kW 40 Efficiency, %, up to 92 Heat Output Regulation Ratio, up to Up to 10 Natural Gas Consumption, m³/h, for units from 40 to 10000 kW 11.8-1300 Air Pressure, Pa 500-3000 Air Flow Rate, m³/h 6000-280000 Air Temperature Rise (Δt), ˚C 25…90 Power Supply Voltage at 50 Hz, V 400/230 Electric Power, kW, for units from 40 to 10000 kW 20-500 Sound Emission Level, dB, not more than 80 Maximum Gas Connection Pressure, MPa, not more than 5.0 Weight, t, not more than 4-100

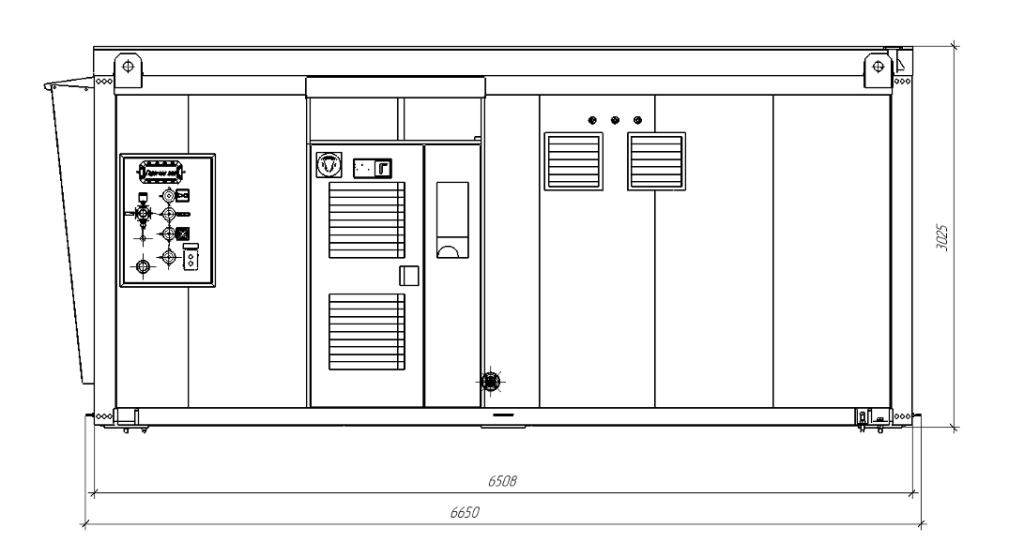

Indicator Name Specifications Climatic Design U, UHL, Placement Category 1 according to GOST 15150 Design Service Life, years, at least 20 Unit Placement Category by Explosion and Fire Hazard according to SP 12.13130.2009 G (Moderate fire hazard) Earthquake Resistance of Placement Area, MSK-64 scale (inclusive), points 6-8 Block Overall Dimensions, mm:

- length, not more than

- width, not more than

- height, not more than2991±12 – 20170

2438±8 – 9000

2591±10 - 3400* Under standard conditions according to GOST 2939 - Таблица 2

- Таблица 3

Description

The design of the AVGM LS series is developed to allow remote monitoring of the operation process, replacement of working components, fast-wearing parts and elements under working conditions, prevention of spontaneous loosening of component fastenings, and protection of the burner from overloads.

The equipment in transport position is resistant to transportation at ambient temperatures ranging from minus 45 to plus 50˚C.

The temperature in the gas burner operating zone reaches up to 800˚C.

AVGM PACKAGING

The metal structures included in the unit are delivered on a pallet with a reinforced wooden frame, packed in polymer film.

The equipment and removable components of the unit are protected from mechanical damage, direct exposure to moisture, dust, dirt, and solar radiation during transportation and loading/unloading operations.

The transport box contains a packing list, operation manuals, and accompanying documents enclosed in a polyethylene film pack (another type of packaging may be used).

Indicator Name Specifications Rated Heat Output, kW 40-10000 Rated Thermal Power, kW 40-10000 Minimum Heat Output, kW 40 Efficiency, %, up to 92 Heat Output Regulation Ratio, up to Up to 10 Natural Gas Consumption, m³/h, for units from 40 to 10000 kW 11.8-1300 Air Pressure, Pa 500-3000 Air Flow Rate, m³/h 6000-280000 Air Temperature Rise (Δt), ˚C 25…90 Power Supply Voltage at 50 Hz, V 400/230 Electric Power, kW, for units from 40 to 10000 kW 20-500 Sound Emission Level, dB, not more than 80 Maximum Gas Connection Pressure, MPa, not more than 5.0 Weight, t, not more than 4-100

Indicator Name Specifications Climatic Design U, UHL, Placement Category 1 according to GOST 15150 Design Service Life, years, at least 20 Unit Placement Category by Explosion and Fire Hazard according to SP 12.13130.2009 G (Moderate fire hazard) Earthquake Resistance of Placement Area, MSK-64 scale (inclusive), points 6-8 Block Overall Dimensions, mm:

- length, not more than

- width, not more than

- height, not more than2991±12 – 20170

2438±8 – 9000

2591±10 - 3400* Under standard conditions according to GOST 2939

Description

The design of the AVGM LS series is developed to allow remote monitoring of the operation process, replacement of working components, fast-wearing parts and elements under working conditions, prevention of spontaneous loosening of component fastenings, and protection of the burner from overloads.

The equipment in transport position is resistant to transportation at ambient temperatures ranging from minus 45 to plus 50˚C.

The temperature in the gas burner operating zone reaches up to 800˚C.

AVGM PACKAGING

The metal structures included in the unit are delivered on a pallet with a reinforced wooden frame, packed in polymer film.

The equipment and removable components of the unit are protected from mechanical damage, direct exposure to moisture, dust, dirt, and solar radiation during transportation and loading/unloading operations.

The transport box contains a packing list, operation manuals, and accompanying documents enclosed in a polyethylene film pack (another type of packaging may be used).