Submit a Request and Get a Free Consultation

Submit a request, and we will contact you to provide consultation on any questions

Air heat generators on gas and diesel

HRS Series Heat Generators

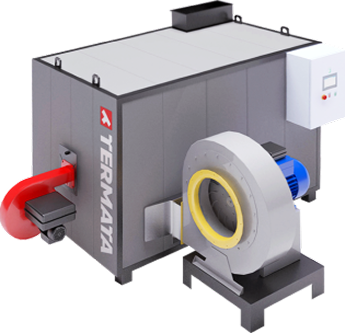

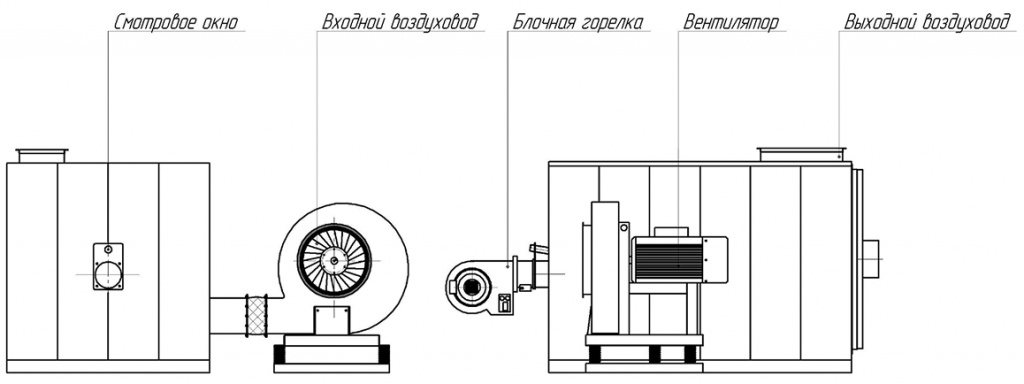

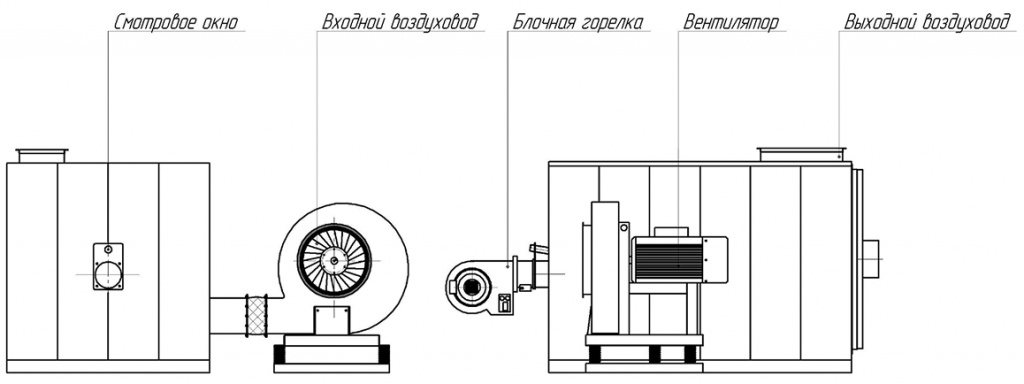

The TERMATA HRS High-Temperature Heat Generator is an autonomous, thermally insulated heating unit consisting of a triple-flow heat exchange block, an automatic block burner operating on natural gas or diesel fuel, and a high-pressure fan. It is designed for heating and warming inert materials such as sand, gravel-sand mixtures (GSM), crushed stone, and others.The triple-flow design of the heat generator's heat exchange block creates a high pressure of dry hot air, enabling quick and efficient thawing and heating of inert materials during concrete production in winter. The heat exchange block is made of special grades of heat-resistant stainless steel, ensuring reliability and a long service life.

Modification year — 2014

- Таблица 1

Model HRS 200 HRS 350 HRS 600 HRS 1000 Total power, kW 200 350 600 1000 Fuel type Diesel fuel, natural gas Maximum diesel fuel consumption, kg/h 25,3 35,9 57 100 Maximum consumption of natural gas, m3/h 32,8 47,3 74,2 117 Power supply, V/Ph/Hz

380/3/50 380/3/50 380/3/50 380/3/50 Maximum air temperature at outlet, ºС 200 200 200 200 Efficiency, % 92 92 92 92 Air capacity, m3/h 4000 6000 7000 16000 Pressure, Pa 5000 7000 8000 8000 Consumed electrical power, kW 12 23 31 46

- Таблица 2

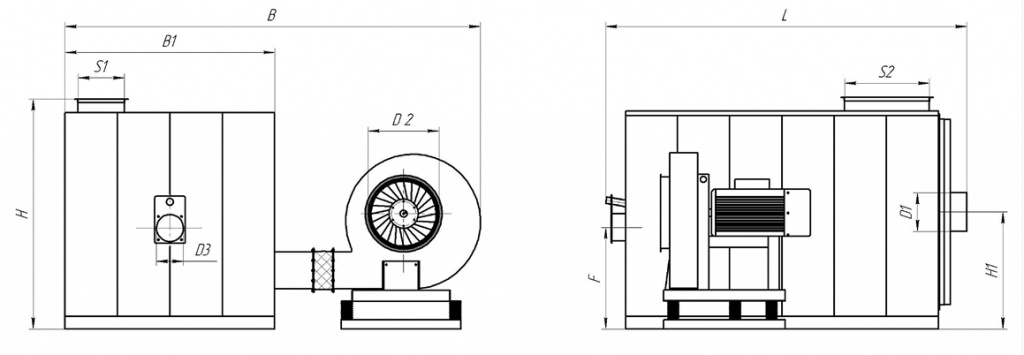

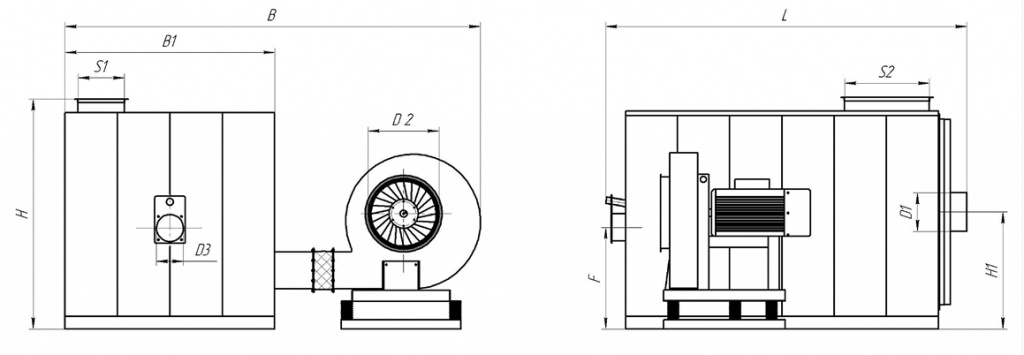

Model HRS 200 HRS 350 HRS 600 HRS 1000 Total length, L 1890 2380 3050 3050 Total width, B 2180 2330 2330 2520 Total height, H 1520 1520 1520 1780 B1 1330 1330 1330 1500 H1 760 760 760 832 D1 250 250 250 300 D2 400 400 400 530 D3 170 170 170 195 F 610 610 610 722 S1 170 170 170 220 S2 500 670 760 760  The TERMATA HRS heat generator is an automated system with a user-friendly interface and does not require the constant presence of personnel. The program allows you to monitor the status of the operating cycle on the screen of the device itself or on a PC, as well as online.

The TERMATA HRS heat generator is an automated system with a user-friendly interface and does not require the constant presence of personnel. The program allows you to monitor the status of the operating cycle on the screen of the device itself or on a PC, as well as online.

The heat generator can be installed both indoors and outdoors. The compact dimensions of the device do not require special installation conditions and also allow it to be moved if necessary.

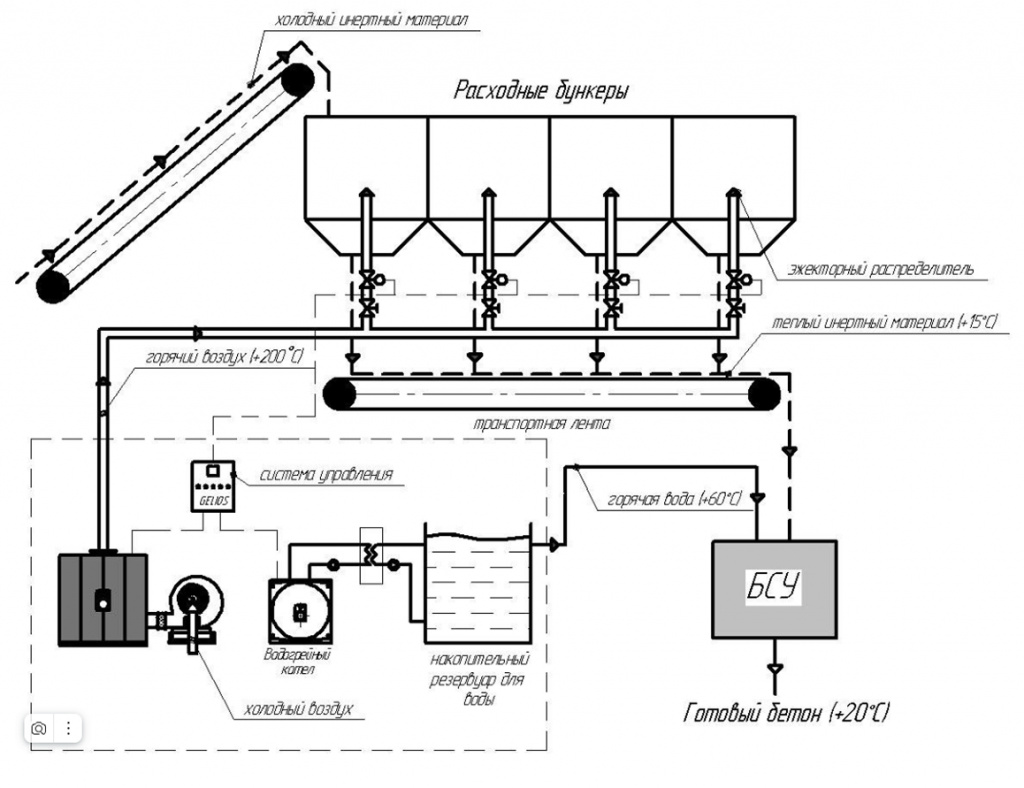

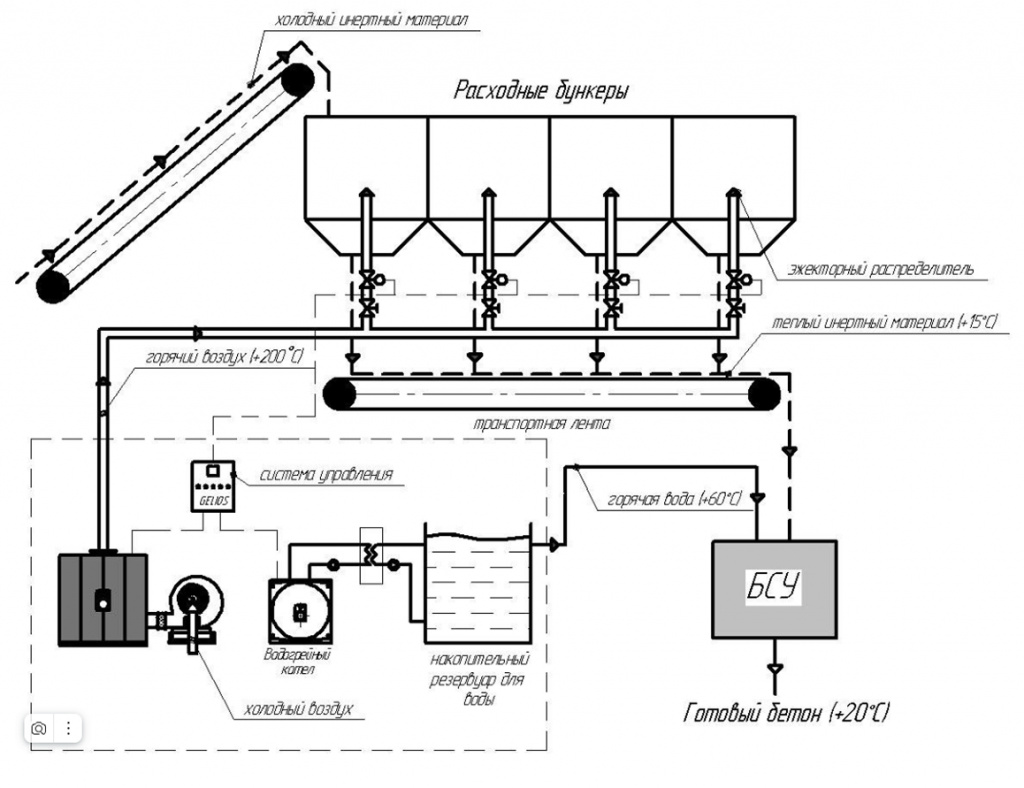

The heating system is used at negative ambient temperatures, as well as when it is necessary to remove moisture from inert materials.The operating principle of the HRS heating system

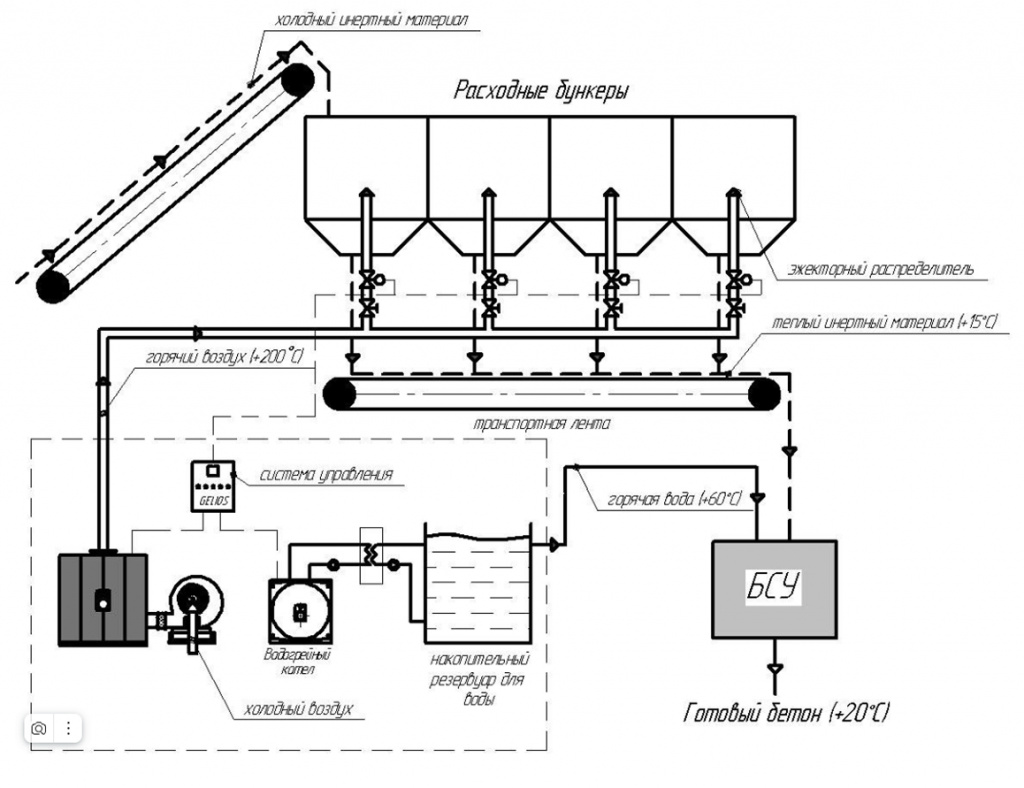

Cold air is drawn from outside or directly from the factory premises. Using a high-pressure fan, the cold air enters the heat generator and is heated up to 200°C. The heated air, through insulated air ducts under a pressure of 7000 Pa, is supplied to the lower part of the расходные бункера (expendable bins) or other loading areas for inert materials via wedge-shaped distributors. Thanks to the arrangement of the collectors, the hot air is evenly distributed from bottom to top, heating the material and preparing it for feeding onto the conveyor and БСУ (batching plant). In parallel with the heat generator, a water boiler heats the water in a specially insulated tank and constantly maintains the set temperature.

Thus, the TERMATA HRS heating system prepares all the main components and allows for the dispatch of concrete with a temperature of at least +20 ºС at any time of the year.

- Таблица 3

The TERMATA HRS heat generator is an automated system with a user-friendly interface that does not require constant personnel presence. The program allows monitoring the status of the operating cycle on the device’s screen or a PC, as well as in online mode.

The installation of the heat generator is possible both indoors and outdoors. The compact dimensions of the device do not require special installation conditions and also allow it to be moved if necessary.

The operating principle of the HRS heating system

The heating system is used at negative ambient temperatures and in cases requiring the removal of moisture from inert materials.

Cold air is drawn from either the outdoors or the plant itself. Using a high-pressure fan, the cold air is directed into a heat generator and heated to 200°C. The heated air is then delivered through insulated air ducts at a pressure of 7000 Pa to the lower part of storage hoppers or other loading points for inert materials via wedge-shaped distributors. Thanks to the arrangement of the collectors, the hot air is evenly distributed from bottom to top, heating the material and preparing it for transfer to the conveyor and the batch mixing plant (BSU). Simultaneously, a hot water boiler, operating in parallel with the heat generator, heats water in a specially insulated reservoir and maintains a set temperature at all times.

Thus, the TERMATA HRS heating system prepares all key components and enables the dispatch of concrete at a temperature no lower than +20°C year-round.

Model HRS 200 HRS 350 HRS 600 HRS 1000 Total power, kW 200 350 600 1000 Fuel type Diesel fuel, natural gas Maximum diesel fuel consumption, kg/h 25,3 35,9 57 100 Maximum consumption of natural gas, m3/h 32,8 47,3 74,2 117 Power supply, V/Ph/Hz

380/3/50 380/3/50 380/3/50 380/3/50 Maximum air temperature at outlet, ºС 200 200 200 200 Efficiency, % 92 92 92 92 Air capacity, m3/h 4000 6000 7000 16000 Pressure, Pa 5000 7000 8000 8000 Consumed electrical power, kW 12 23 31 46

Model HRS 200 HRS 350 HRS 600 HRS 1000 Total length, L 1890 2380 3050 3050 Total width, B 2180 2330 2330 2520 Total height, H 1520 1520 1520 1780 B1 1330 1330 1330 1500 H1 760 760 760 832 D1 250 250 250 300 D2 400 400 400 530 D3 170 170 170 195 F 610 610 610 722 S1 170 170 170 220 S2 500 670 760 760  The TERMATA HRS heat generator is an automated system with a user-friendly interface and does not require the constant presence of personnel. The program allows you to monitor the status of the operating cycle on the screen of the device itself or on a PC, as well as online.

The TERMATA HRS heat generator is an automated system with a user-friendly interface and does not require the constant presence of personnel. The program allows you to monitor the status of the operating cycle on the screen of the device itself or on a PC, as well as online.

The heat generator can be installed both indoors and outdoors. The compact dimensions of the device do not require special installation conditions and also allow it to be moved if necessary.

The heating system is used at negative ambient temperatures, as well as when it is necessary to remove moisture from inert materials.The operating principle of the HRS heating system

Cold air is drawn from outside or directly from the factory premises. Using a high-pressure fan, the cold air enters the heat generator and is heated up to 200°C. The heated air, through insulated air ducts under a pressure of 7000 Pa, is supplied to the lower part of the расходные бункера (expendable bins) or other loading areas for inert materials via wedge-shaped distributors. Thanks to the arrangement of the collectors, the hot air is evenly distributed from bottom to top, heating the material and preparing it for feeding onto the conveyor and БСУ (batching plant). In parallel with the heat generator, a water boiler heats the water in a specially insulated tank and constantly maintains the set temperature.

Thus, the TERMATA HRS heating system prepares all the main components and allows for the dispatch of concrete with a temperature of at least +20 ºС at any time of the year.

The TERMATA HRS heat generator is an automated system with a user-friendly interface that does not require constant personnel presence. The program allows monitoring the status of the operating cycle on the device’s screen or a PC, as well as in online mode.

The installation of the heat generator is possible both indoors and outdoors. The compact dimensions of the device do not require special installation conditions and also allow it to be moved if necessary.

The operating principle of the HRS heating system

The heating system is used at negative ambient temperatures and in cases requiring the removal of moisture from inert materials.

Cold air is drawn from either the outdoors or the plant itself. Using a high-pressure fan, the cold air is directed into a heat generator and heated to 200°C. The heated air is then delivered through insulated air ducts at a pressure of 7000 Pa to the lower part of storage hoppers or other loading points for inert materials via wedge-shaped distributors. Thanks to the arrangement of the collectors, the hot air is evenly distributed from bottom to top, heating the material and preparing it for transfer to the conveyor and the batch mixing plant (BSU). Simultaneously, a hot water boiler, operating in parallel with the heat generator, heats water in a specially insulated reservoir and maintains a set temperature at all times.

Thus, the TERMATA HRS heating system prepares all key components and enables the dispatch of concrete at a temperature no lower than +20°C year-round.