Submit a Request and Get a Free Consultation

Submit a request, and we will contact you to provide consultation on any questions

Thermal oil boilers

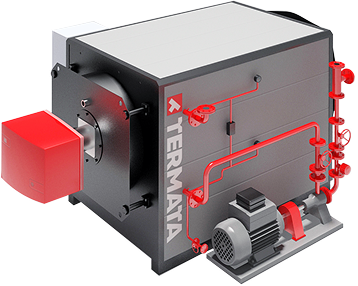

TERMATA KX Thermal Oil Boilers

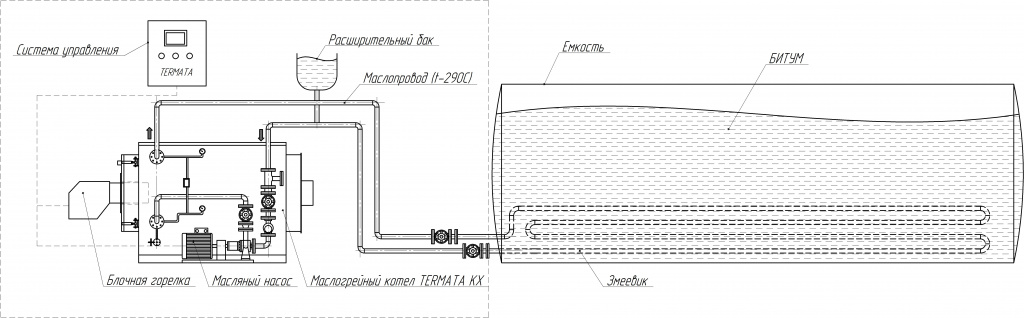

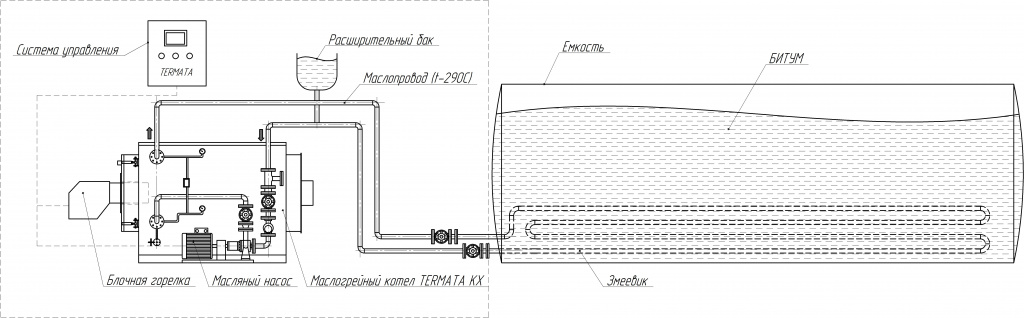

Designed for heating and automatically maintaining temperature during bitumen preparation at asphalt plants. Diathermic oil heats up to 300-360 °C, has high heat capacity, allows precise temperature control, and prevents scale formation on the boiler's internal surfaces, reducing maintenance costs. This heat transfer medium lowers the risk of pipe corrosion compared to water, as it coats the interior and protects against oxygen exposure. Such systems are characterized by high durability.

Modification year — 2016

- Таблица 1

Parameter KX 500 KX 700 KX 1000 KX 1500 KX 2000 KX 2500 KX 3000 Nominal thermal power, kW 500 700 1000 1500 2000 2500 3000 Efficiency % 92 92 92 92 92 92 92 Furnace power, kW 543 761 1087 1630 2174 2717 3261 Max. fuel consumption — diesel, kg/h 50 70 101 160 207 229 350 Max. fuel consumption — natural gas, m³/h 58 81 116 185 229 265 351 Max. outlet oil temperature, °C 290 290 290 290 290 290 290 Oil volume, m³ 0.23 0.3 0.5 0.74 0.95 1.6 1.85 Power supply V/Ph/Hz 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 Weight, kg 1900 2500 3700 3700 Custom design Combustion chamber resistance, mbar 3.2 3.4 3.8 4.2 Minimum pump capacity, m³/h 40 50 80 100 Temperature drop, °C 40 40 40 40 Pressure drop (at t=250°C), mbar 1300 1940 1580 1700

- Таблица 2

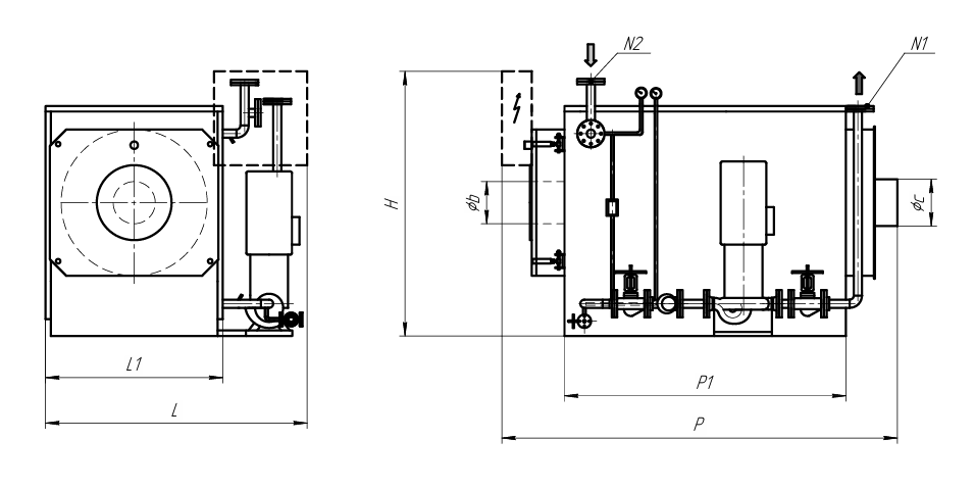

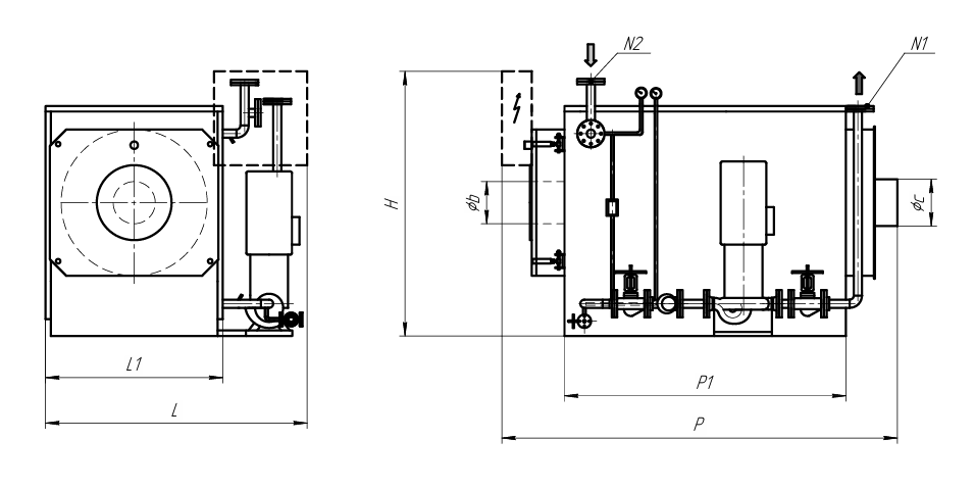

Model H, mm P, mm P1, mm L, mm L1, mm DN N1, mm DN N2, mm DN Øb, mm DN Øc, mm KX 500 1520 4300 2510 1800 1130 57 57 190 300 KX 700 1520 4600 2850 1800 1130 76 76 200 350 KX 1000 1790 5250 3475 2150 1450 89 89 220 400 KX 1500 1790 5250 3475 2150 1450 108 108 220 450 KX 2000 Custom design KX 2500 KX 3000

- Таблица 3

- The distinctive feature of oil-fired boilers is the use of oil as a heat transfer medium. Unlike water, thermal oil heats up linearly and can reach a temperature of 350 °C at a pressure of 10 bar (for comparison, steam at the same temperature requires 180 bar). Diathermic oil ensures uniform heat distribution in technological processes, such as bitumen heating.

Depending on operating temperatures, mineral or synthetic oils are used. Synthetic oils are applied in circuits with temperatures up to 400 °C. The circulation of the heat transfer medium is forced using pumps. The oil in TERMATA boilers does not require purification and lasts 6-7 years.

The thermal oil system with mineral oil is an open system equipped with a degasser to remove oxygen and water vapor, preventing pipe corrosion. As the oil heats up, it expands, so the system includes an expansion tank and a drain tank for the heat transfer medium in case of repairs or maintenance.

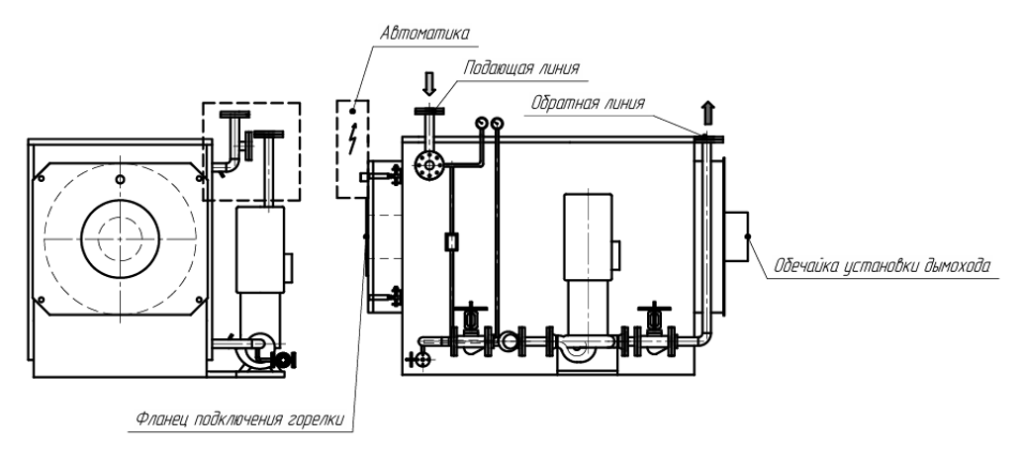

The large-volume combustion chamber has a low thermal load and is protected by tangential tubes. The oil circulation speed is regulated between the combustion chamber and the convection plate to optimize system pressure.

The boiler's outer casing is made of sheet metal with stiffening ribs. Double mineral wool panels provide thermal insulation, and the outer shell is protected by corrugated steel sheets.

Advantages of TERMATA KX Boilers

- Diathermic oil has high density, affecting the heating speed and heat retention.

- The operating temperature reaches 300–360 °C, allowing the boilers to be used in technological processes with high temperature requirements.

- The oil reduces the likelihood of scale formation inside the boiler, which may decrease the need for cleaning.

- Boilers with this heat transfer medium are used in systems requiring a stable temperature regime.

- Temperature parameters contribute to efficient heat distribution.

- Operation at low pressure in pipelines reduces the load on equipment.

- The automated control system does not require constant personnel supervision.

- The heat transfer medium has anti-corrosion properties, impacting the equipment’s service life.

Applications of TERMATA KX Boilers

TERMATA boilers with diathermic oil are actively used in asphalt production, the food industry, petrochemicals, the manufacturing of construction materials, furniture, and roofing—in other words, in areas requiring boilers with a heat transfer medium that heats up to very high temperatures. However, thermal oil boilers are also suitable for domestic use: they are widely utilized by homeowners' associations, new cottage districts, and private sectors. They are also used to conduct chemical reactions, perform hot pressing, and increase the temperature in drying systems.

Design and Operating Principle:

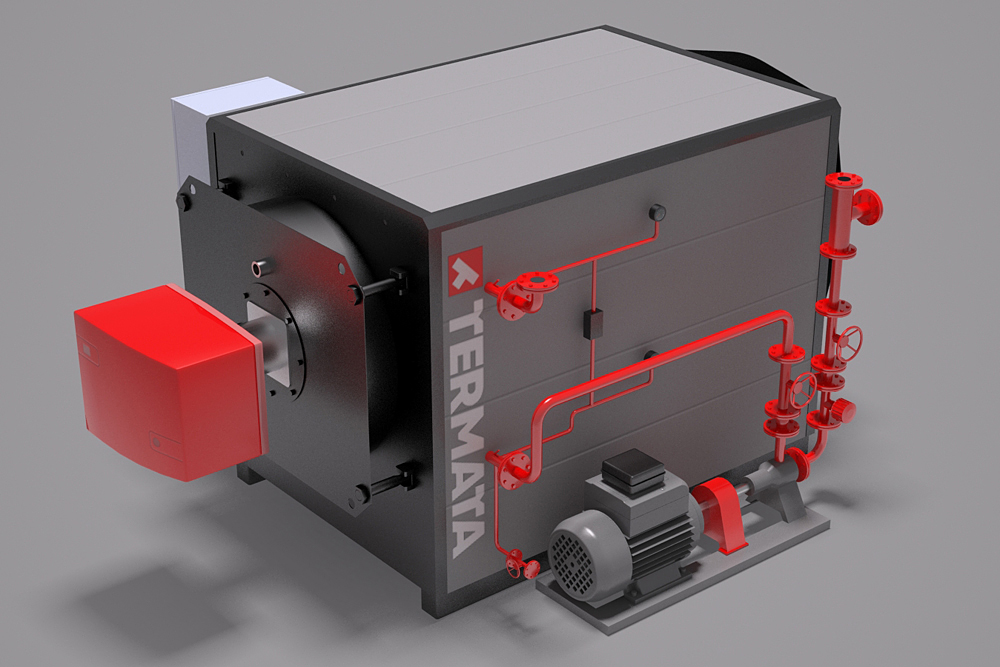

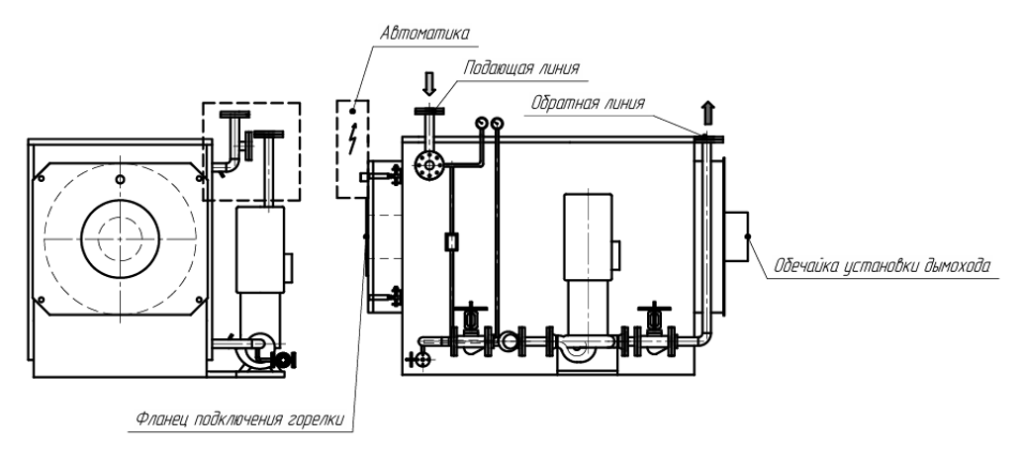

TERMATA thermal oil boilers are horizontally designed with spiral coils. The coils are made of seamless tubes bent into parallel spirals to ensure the separation of different exhaust gas paths.

The first inner spiral coil forms a large-volume combustion chamber to provide high operational flexibility under various consumer-required loads.

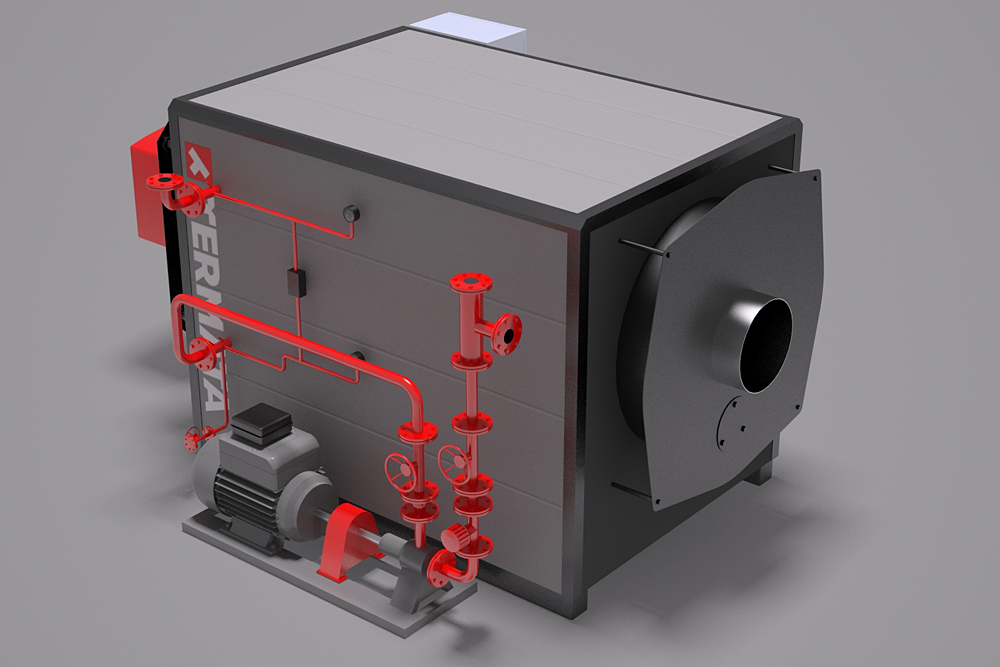

The second coil forms an outer convective bundle for the removal of the second exhaust gas path. The third gas path occurs in the outer cylindrical casing.

The base is made of steel profile (carbon steel), ensuring structural strength and ease of movement, with a working platform and connection for the diathermic oil circulation group provided on the side.

The front door is attached with bolts, easily opens for inspection and cleaning, and is equipped with a burner installation cone and a flame observation window.

Fuel combustion occurs using a block burner. The flame enters the inner cylinder, transfers part of the heat, then reverses and passes along the inner and outer cylinders before reversing again. In the final pass, the flue gases transfer the remaining heat to the outer cylinder and exit through the chimney. Thanks to the extended flame path, the system’s efficiency is at least 92%.

Parameter KX 500 KX 700 KX 1000 KX 1500 KX 2000 KX 2500 KX 3000 Nominal thermal power, kW 500 700 1000 1500 2000 2500 3000 Efficiency % 92 92 92 92 92 92 92 Furnace power, kW 543 761 1087 1630 2174 2717 3261 Max. fuel consumption — diesel, kg/h 50 70 101 160 207 229 350 Max. fuel consumption — natural gas, m³/h 58 81 116 185 229 265 351 Max. outlet oil temperature, °C 290 290 290 290 290 290 290 Oil volume, m³ 0.23 0.3 0.5 0.74 0.95 1.6 1.85 Power supply V/Ph/Hz 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 Weight, kg 1900 2500 3700 3700 Custom design Combustion chamber resistance, mbar 3.2 3.4 3.8 4.2 Minimum pump capacity, m³/h 40 50 80 100 Temperature drop, °C 40 40 40 40 Pressure drop (at t=250°C), mbar 1300 1940 1580 1700

Model H, mm P, mm P1, mm L, mm L1, mm DN N1, mm DN N2, mm DN Øb, mm DN Øc, mm KX 500 1520 4300 2510 1800 1130 57 57 190 300 KX 700 1520 4600 2850 1800 1130 76 76 200 350 KX 1000 1790 5250 3475 2150 1450 89 89 220 400 KX 1500 1790 5250 3475 2150 1450 108 108 220 450 KX 2000 Custom design KX 2500 KX 3000

- The distinctive feature of oil-fired boilers is the use of oil as a heat transfer medium. Unlike water, thermal oil heats up linearly and can reach a temperature of 350 °C at a pressure of 10 bar (for comparison, steam at the same temperature requires 180 bar). Diathermic oil ensures uniform heat distribution in technological processes, such as bitumen heating.

Depending on operating temperatures, mineral or synthetic oils are used. Synthetic oils are applied in circuits with temperatures up to 400 °C. The circulation of the heat transfer medium is forced using pumps. The oil in TERMATA boilers does not require purification and lasts 6-7 years.

The thermal oil system with mineral oil is an open system equipped with a degasser to remove oxygen and water vapor, preventing pipe corrosion. As the oil heats up, it expands, so the system includes an expansion tank and a drain tank for the heat transfer medium in case of repairs or maintenance.

The large-volume combustion chamber has a low thermal load and is protected by tangential tubes. The oil circulation speed is regulated between the combustion chamber and the convection plate to optimize system pressure.

The boiler's outer casing is made of sheet metal with stiffening ribs. Double mineral wool panels provide thermal insulation, and the outer shell is protected by corrugated steel sheets.

Advantages of TERMATA KX Boilers

- Diathermic oil has high density, affecting the heating speed and heat retention.

- The operating temperature reaches 300–360 °C, allowing the boilers to be used in technological processes with high temperature requirements.

- The oil reduces the likelihood of scale formation inside the boiler, which may decrease the need for cleaning.

- Boilers with this heat transfer medium are used in systems requiring a stable temperature regime.

- Temperature parameters contribute to efficient heat distribution.

- Operation at low pressure in pipelines reduces the load on equipment.

- The automated control system does not require constant personnel supervision.

- The heat transfer medium has anti-corrosion properties, impacting the equipment’s service life.

Applications of TERMATA KX Boilers

TERMATA boilers with diathermic oil are actively used in asphalt production, the food industry, petrochemicals, the manufacturing of construction materials, furniture, and roofing—in other words, in areas requiring boilers with a heat transfer medium that heats up to very high temperatures. However, thermal oil boilers are also suitable for domestic use: they are widely utilized by homeowners' associations, new cottage districts, and private sectors. They are also used to conduct chemical reactions, perform hot pressing, and increase the temperature in drying systems.

Design and Operating Principle:

TERMATA thermal oil boilers are horizontally designed with spiral coils. The coils are made of seamless tubes bent into parallel spirals to ensure the separation of different exhaust gas paths.

The first inner spiral coil forms a large-volume combustion chamber to provide high operational flexibility under various consumer-required loads.

The second coil forms an outer convective bundle for the removal of the second exhaust gas path. The third gas path occurs in the outer cylindrical casing.

The base is made of steel profile (carbon steel), ensuring structural strength and ease of movement, with a working platform and connection for the diathermic oil circulation group provided on the side.

The front door is attached with bolts, easily opens for inspection and cleaning, and is equipped with a burner installation cone and a flame observation window.

Fuel combustion occurs using a block burner. The flame enters the inner cylinder, transfers part of the heat, then reverses and passes along the inner and outer cylinders before reversing again. In the final pass, the flue gases transfer the remaining heat to the outer cylinder and exit through the chimney. Thanks to the extended flame path, the system’s efficiency is at least 92%.